|

There are many models for making improvements, all of which try to provide a

set of actions or steps that can be learned and followed.

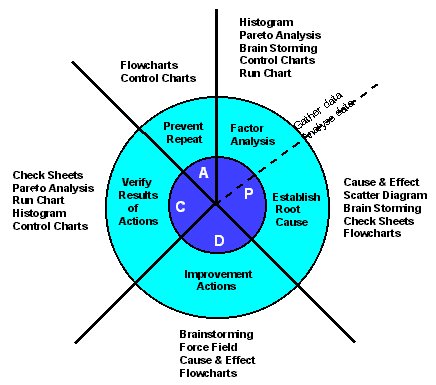

The Plan - Do - Check - Act ( P - D - C - A ) cycle has been in use for many years,

it provides an easily learned format and straight forward guidance on use of quality

tools.

|

|

Overview

Plan

- Gather all of the data and information appertaining to the concern or problem.

- Establish all of the possible causes of the problem and agree on (define) the

root cause. Trials to prove the root cause may be necessary.

- Develop a solution and action plan.

Do

- Implement the solution or corrective action.

Check

- Monitor and confirm the results of the action.

Act

- Act on learning to prevent recurrence of the problem. Standardise on best

practice where possible.

Methodology

Plan

- Gather the data

- Obtain facts, ideally as measured or counted data.

- Process and product measurements are the best source of facts.

- Never rely upon guesswork or opinions.

- Establish possible causes

- Brainstorming is very important.

- Flowcharts are used to focus on process factors.

- Cause and Effect diagrams can illustrate possibilities.

- All possible causes should be examined.

- When final identification amounts to guesswork, trials should be carried out.

- Check Sheets and Scatter Diagrams are useful for trials.

- Trials should give measurements or counts for objective decision making.

Do

- Implement solution

- Use experience and common-sense to identify corrective action.

- Brainstorming, Cause and Effect Diagrams and Force Field Analysis can all

be used to identify the most promising solution.

Check

- Monitor and verify results of action

- Check Sheets, Pareto Analysis, Run Charts, Histograms can all be used to

measure change, as can the more informative Control Chart.

Act

- Prevent recurrence

- Change process.

- Ensure all documentation is up to date.

- Ensure changes are visible. Flowcharts and Control Charts are useful.

- Review if solution can be applied to other products / processes.

- Ensure changes are followed up by work team training.

| Tool Type |

Identify Problem |

Establish Root Cause |

Problem Solution |

Verify Actions |

Section |

| Brainstorming | # | # | # | | 2.2 |

| Flowchart | | # | # | | 2.3 |

| Scatter Diagram | | # | | | 2.4 |

| Pareto Analysis | # | | | # | 2.5 |

| Histogram | # | | | # | 2.6 |

| Run Chart | # | | | # | 2.7 |

| Force Field Analysis | | | # | |

2.8 |

| Check-sheet | | # | | # | 2.9 |

| Cause & Effect Diagram | | # | # | | 2.10 |

| Control Charts | # | | | | 2.11 |

|