| The Elements of Agility |

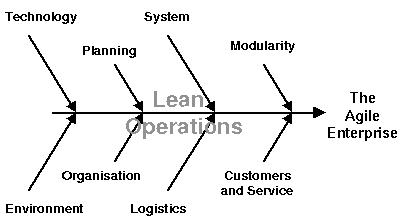

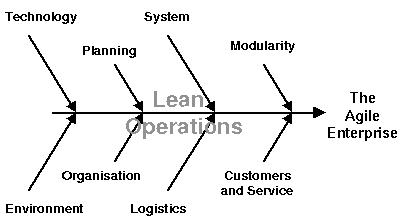

If Lean establishes the foundation for Agile Manufacturing, what are the additional factors that extend traditional Lean to become more Agile. We may represent this as a fishbone diagram. See the figure.

The central spine of the fish is Lean Operations itself. This is the backbone, without which there can be no Agility. The "enablers" for Agility are the bones. These are:

Technology: These are the technologies of flexible manufacturing. Robots, CAD, NC/CNC. They include small footprint machines with services at the back. They are not the seemingly flexible (but actually wasteful, inflexible) large automated transfer lines, large machining centres, FMS, and the AS/RS (except possibly in distribution).

Planning: Flexible planning tools including finite scheduling when used for planning, but not for execution. Not MRPII used for control, although MPS would often be used and MRP sometimes used for planning where appropriate. ERP, but only using the minimum necessary modules, and then only for planning. And only after much simplification and waste reduction. Specialist simulation tools used for planning and "what if".

System: The use of networking, the Internet, and appropriate e commerce. Especially to link a network of suppliers, and to transfer designs and specifications electronically. To enter customer orders and specifications. The ability to learn about customer requirements quickly. Configurators. Computers to speed response times and improve service. Used horizontally rather than in vertical silos.

Modularity: The supreme way of achieving flexibility, as well as cost, quality and delivery. It is the enabling principle for networks of suppliers to use their own expertise and combining it with that of others for mutual advantage. Already well established in computer and car design, new forms are beginning to appear. In VW's Brazilian truck plant suppliers use their own workforce on VW's assembly line to build the vehicle. Subcontracting of computer services is not unusual. Fidelity Investments use an outside firm to run one of its funds.

Organisation: In company and inter-company. In company including streamlined, process oriented organisation structures and HR policies that encourage innovation, improvement and participation. What Sasser calls the "Service Profit Chain" with employee capability, employee satisfaction, employee loyalty, leading to employee productivity, leading to customer satisfaction and customer loyalty, feeding back to further employee capability, satisfaction, and loyalty. Inter-company organisation including building partnership and trust along the supply chain. This also includes the use of appropriate, parsimonious control and measurement systems. The measures and controls must encourage, not discourage Lean. Open Book management.

Customers and Service: Although Womack and Jones' first principle is to begin with the customer, agility means flexibility in product offerings and design up and beyond the point of delivery. "Mass customisation" as well as "Quick Response" will become the norm. This goes beyond the 4 P's of marketing to include the product-service bundle, and to work towards customer retention, referrals, and repeat business. Managing all customer "moments of truth".

Environment: Managing processes in an environmentally responsible yet profitable way. Concerned with Redesign for life cycles, Reducing materials and energy, Recovering materials and energy during manufacture and use, Recycling after product use, and Remanufacturing.

Logistics: Running the supply or demand chain for agility. This includes the technology of agile logistics (cross-docking, small unit distribution), the "software" (quick response systems, EDI, EPOS), and selecting and tailoring appropriate channels to focused customer groupings (like Coke's multi channel distribution system each tailored for a specific customer requirement, rather than for overall cost reduction).