To help categorise the type of variation, Dr. W.E. Deming names two types of variation that can help underpin what requires improvement.

Common Causes

|

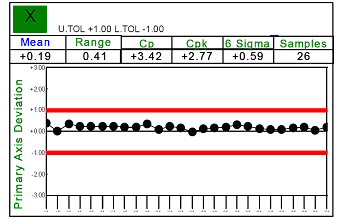

Common causes are inherent and predictable types of variation in the process and affect, in some extent, all products/inputs to the process [1]. Processes subject to common cause variation will exhibit stable and consistent patterns of variation over time as shown in Figure 2. Examples of this would include:-

|

Figure 2: An example of a process output

|

Special Causes

|

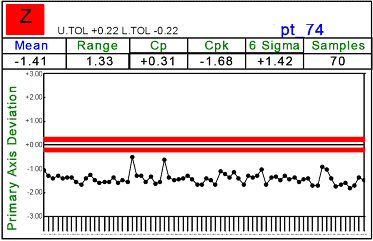

Special Causes are momentary in nature and are not inherent in the process. They will affect only some products of the process and the overall output. Processes subject to special causes will exhibit unpredictable patterns of variation, which change overtime. Examples of Special Causes may include:

Special Causes must always be investigated as soon as possible after its presence have been highlighted as it may have an adverse effect on the process and its output as shown in the example of Figure 3. |

Figure 3: An example of a process output containing special cause variation |

Click the buttons at the top for more information.

Page 7 out of 15